Grocery cold rooms

Cold room temperature: +3 °C to +5 °C

Air cooler temperature difference: 8 K

Cooling performance designed for PUR panels of min. thickness 60 mm. The cooling kits are designed for storage of pre-cooled goods.

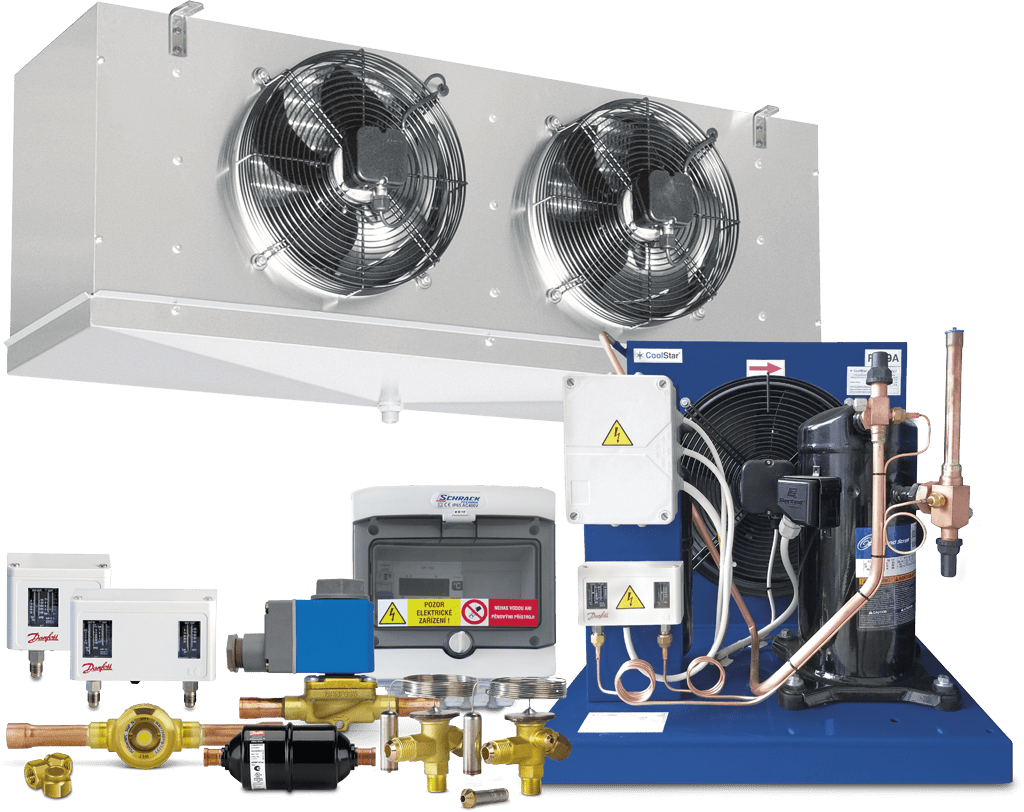

Standard unit content: condensing unit, unit cooler without electric defrost, switchboard with Dixell XR70D controller, thermostatic expansion valve, filter drier, sight glass, dual pressure switch, flare nuts

Vegetable and fruit coldrooms

Cold room temperature: +3 °C to +5 °C

Air cooler temperature difference: 6 K

Cooling performance designed for PUR panels of min. thickness 60 mm. The cooling kits are designed for storage of pre-cooled goods.

Standard unit content: condensing unit, unit cooler without electric defrost, switchboard with Dixell XR70D controller, thermostatic expansion valve, filter drier, sight glass, dual pressure switch, flare nuts

Meat cold rooms

Cold room temperature: –2 °C to +2 °C

Air cooler temperature difference: 7 K

Cooling performance designed for PUR panels of min. thickness 60 mm. The cooling kits are designed for storage of pre-cooled goods.

Standard unit content: condensing unit, unit cooler with electric defrost, switchboard with Dixell XR70D controller, thermostatic expansion valve, filter drier, sight glass, solenoid valve, dual pressure switch, flare nuts

Cold processing rooms

Cold room temperature: +12 °C to +15 °C

Air cooler temperature difference: 9 K

Standard unit content: condensing unit, dual discharge unit cooler without electric defrost, switchboard with Dixell XR70D controller, thermostatic expansion valve, filter drier, sight glass, dual pressure switch, flare nuts

Freezer rooms

Cold room temperature: –20 °C to –18 °C

Air cooler temperature difference: 7 K

Cooling performance designed for PUR panels of min. thickness 100 mm. The cooling kits are designed for storage of pre-frozen goods.

Standard unit content: condensing unit, unit cooler with electric defrost, switchboard with Dixell XR70D controller, thermostatic expansion valve with MOP, filter drier, sight glass, solenoid valve, dual pressure switch, flare nuts

Optional equipment

We install additional equipment according to the customer’s request:

- crankcase heater

- condensing pressure control by fan cycling

- fan speed control

- phase sequence monitoring

Optional accessories

We supply additional components to the cooling kits according to the customer’s request:

- crankcase heater

- high-pressure pressure switch + capillary connection + mounting bracket

- electronic fan speed controller + connecting cable

outdoor unit cover